HPMSM - EV Fuel

Element 25 fly-through of proposed HPMSM Plant Model

Manganese has historically been used in the steel industry which consumes approximately 90% of the manganese produced globally. The balance is used in high purity applications such as electrolytic manganese metal (EMM), electrolytic manganese dioxide (EMD) and HPMSM. Lower purity manganese sulphate is also used as an important fertiliser and animal trace nutrient in the farming and agricultural industries. These “fertiliser grade” manganese sulphate products are not suitable for Electric Vehicle (EV) battery applications.

Manganese is an increasingly critical part of the global pursuit of sustainable energy solutions, particularly as a key raw material in the production of EV batteries.

The Rise of Electric Vehicles

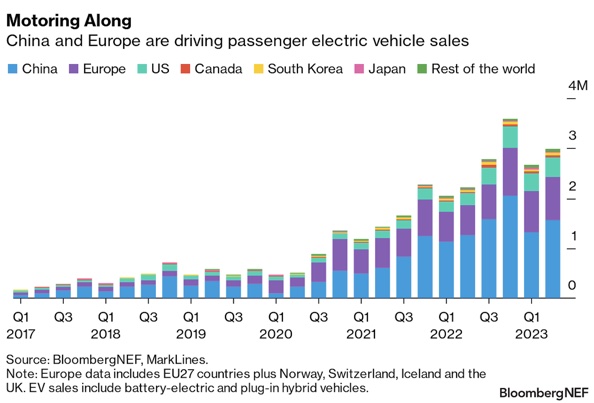

Passenger EV sales are continuing to grow, with almost 14 million new electric cars being registered in 2023. EV sales were 3.5 million higher than in 2022, representing a 35% year-on-year increase, and EVs accounted for around 18% of all cars sold in 2023 (up from 14% in 2022). In 2024, EV sales are expected to reach 16.6 million, indicating that growth remains robust as electric car markets mature.1

Passenger EV sales are continuing to grow, with almost 14 million new electric cars being registered in 2023. EV sales were 3.5 million higher than in 2022, representing a 35% year-on-year increase, and EVs accounted for around 18% of all cars sold in 2023 (up from 14% in 2022). In 2024, EV sales are expected to reach 16.6 million, indicating that growth remains robust as electric car markets mature.1

Battery electric cars accounted for 70% of the electric car stock in 2023. The most commonly used manganese feedstock for lithium-ion batteries is a very high purity manganese sulphate, commonly known as High Purity Manganese Sulphate Monohydrate (HPMSM). HPMSM has the chemical formula MnSO4.H2O.

HPMSM is currently a relatively small portion of the overall Manganese industry; however, it is expected that demand from batteries could make up 30% of the market in 20301.

Manganese in Electric Vehicle Batteries

HPMSM demand growth is driven by the increasing consumption of manganese due to the EV industry’s adoption of manganese-based lithium-ion batteries (LIB) cathode chemistries. Manganese is contained in the majority of the cathode chemistries used in EVs including:

|

LMFP:

|

Lithium-Manganese-Iron-Phosphate

|

|

LNMO:

|

Lithium-Nickel-Manganese Oxide

|

|

LMO:

|

Lithium-ion Manganese Oxide

|

|

NMCA:

|

Nickel-Manganese-Cobalt-Aluminum

|

|

NMC:

|

Nickel-Manganese-Cobalt

|

|

LMR:

|

Lithium-Manganese Rich

|

Lithium-Manganese-Rich (LMR), Lithium Manganese Iron Phosphate (LMFP) and Lithium Manganese Nickel Oxide (LMNO) batteries are at the forefront of cutting-edge battery technologies. These innovative battery systems harness the unique properties of manganese in combination with other elements to deliver enhanced performance, safety, and efficiency.

The advantages of high manganese cathode technologies include:

Enhanced Energy Density: The incorporation of manganese-rich cathode materials in LMR batteries contributes to higher energy density, enabling electric vehicles (EVs) to achieve extended driving ranges and longer-lasting charges.

Improved Cycle Life: LMR batteries exhibit improved cycle life, meaning they can undergo a greater number of charge and discharge cycles without significant degradation. This longevity makes them suitable for long-term energy storage solutions.

Reduced Cost: With a reduced reliance on expensive cobalt and a higher abundance of manganese, LMR batteries can potentially lower the overall cost of battery production, thus promoting wider adoption of electric vehicles and renewable energy systems.

Safety and Stability: The presence of manganese contributes to thermal stability, reducing the risk of overheating and thermal runaway. This feature is crucial for ensuring the safety of battery systems.

LMR Batteries:

Looking into the near future, LMR batteries are emerging as a pivotal innovation, harnessing the synergy of lithium, manganese, and other elements to redefine the landscape of energy storage.

LMR batteries typically include a high proportion of manganese alongside other transition metals, such as nickel and cobalt in the cathode. LMR batteries can deliver increased energy density (which equates to vehicle range) while maintaining excellent thermal stability.

LMR batteries are pivotal players in the global shift toward sustainable energy sources and cleaner transportation. As the demand for electric vehicles and grid-scale energy storage continues to surge, LMR batteries offer a compelling solution to address the challenges of energy storage and distribution. Their inherent advantages align with the goals of reducing greenhouse gas emissions, promoting renewable energy integration, and creating a more sustainable energy landscape.

LMFP Batteries:

LMFP batteries combine lithium, manganese, iron, and phosphate to create a cathode material known for its exceptional thermal stability and long cycle life. These attributes make LMFP batteries a preferred choice for applications that prioritize safety and longevity.

While some LMFP batteries may offer slightly lower energy density compared to other technologies such as LMNO, their robustness and resistance to thermal runaway make them ideal for many EV applications. The latest developments, such as Gotion’s “1000 km” LMFP battery are solving some of the early energy density challenges, making LMFP an even more attractive solution. Tesla’s latest iteration of the Model 3, for example, is going to use an LMFP battery chemistry known as M3P to harness these benefits.

LMNO Batteries:

Lithium Manganese Nickel Oxide (LMNO) batteries, incorporate manganese, nickel, and oxygen into their cathode structure. This blend facilitates higher energy density, delivering increased driving ranges and improved performance for electric vehicles. LMNO batteries exhibit a balanced compromise between energy density, cost, and safety.

Who is Using Manganese?

Volkswagen, Mercedes, Tesla, and GM are among the companies that have announced intentions to use more high-purity manganese in their cars. A Chevy Bolt, for example, can contain over 24 kg of manganese.

“The reason nobody is talking about manganese is that it’s very cheap, and it’s taken for granted,” said Andrew Zemek, special adviser at CPM Group.

But Element 25 would argue therein lies its main strength. As the world looks for safer, cleaner, ethical raw materials to transform the global energy architecture, manganese offers a number of solutions as the battery material of choice.

Increasing demand from the EV industry and the subsequent deficit of high-purity manganese is expected to have a strong impact on manganese demand and the success of Element 25 as a leading high purity manganese company.

The synergy between manganese and other elements in LMR. LMFP and LMNO batteries represents a remarkable leap forward in battery technology for electric vehicles. These advancements drive us closer to a future defined by sustainable transportation and clean energy. As these battery technologies continue to evolve, we can anticipate a broader array of electric car models harnessing the power of manganese to redefine the automotive landscape.

The Future of Manganese in EV Battery Technology:

The future brims with tantalising prospects as manganese pioneers the evolution of battery technology for electric vehicles. Intensive research is forging ahead to engineer advanced manganese-based materials that promise heightened energy storage capacities, enhanced charging efficiency, and prolonged battery lifespans. This trajectory aligns manganese with the dynamic demands of EVs, facilitating seamless integration of renewable energy, lengthened driving ranges, and accelerated charging times. The inherent abundance of manganese underscores its potential to revolutionise not only transportation but also energy grids, ushering in a new era of sustainable power distribution.

The multifaceted allure of manganese spans its intricate chemistry, historical legacy, pivotal role in steel production, and its groundbreaking influence on the electric vehicle battery landscape. With every charge of an EV, manganese propels us forward into a future powered by clean energy and innovation. In this brief introduction, we have only scratched the surface of this extraordinary element's contributions – should you seek a deeper exploration or have inquiries, please do not hesitate to connect with us.

Further Reading:

Trends in electric cars

Gotion unveils LMFP battery it says can deliver 1,000km per charge (electrek.co)

Tesla to Equip Revamped Model 3 in China with CATL New Battery, Report Says - Cnevpost - Batteries News

It’s not all about lithium - here’s why manganese is the ultimate battery metals quiet achiever - Stockhead

Manganese Could Be the Secret Behind Truly Mass-Market EVs - IEEE Spectrum